Texture is an important component for food and beverage companies that are looking to develop new product lines that excite consumers. Named by Mintel a key trend, texture is the newest tool to help engage consumers. In a recent article, Pecan Deluxe Candy’s Account Director, Adam Utley discusses how texture is driving the key trends (listed below) for QSR desserts.

Hero Ingredients

Texture-based ingredients are particularly important because they are responsible for delivering much of a food product’s flavor and consistency, and inclusions have always had a massive part to play in lines such as ice cream, chilled desserts, baked goods and beverages. Now, however, the climate is shifting and inclusions are coming into their own as the “hero” product, no longer an accessory.

Inclusions currently in demand across Europe can be found enhancing soft serve ice cream, as well as beverages such as milkshakes. An increasing number of restaurants are using hero pieces as the focal point of their products; they are no longer broken up or blended into the product – they are the focus in their own right.

Soft Serve as a Platform for Texture

According to Utley, soft serve products are perfect for showcasing inclusions and larger sized products have been the focus of many leading fast food chains’ soft serve desserts across Europe. For example, chunky cookie dough pieces will feature in a German QSR’s dessert line and salted fudge pieces are key to a new soft serve at a Portuguese fast food chain.

If we look at these particular products, texture is a key focus across each of them. When fudge pieces are added to soft serve ice creams minutes before serving, there is no time for the fudge to chill or freeze, and the soft bite that the consumer would expect from the confection is ensured. Cookie dough itself has a unique texture, and when incorporated into a soft serve ice cream the pieces are often blended up and the consumer is left with a combination of three different textures in one mouthful. First, the smooth, cold nature of the ice cream, second the gritty crunch of the cookie dough piece and to finish, the slight bite of chocolate chip.

The Challenge of Portioning

In fast food chains, where quick service is key, inclusions must be easy to serve with consistent sizing to ensure regular delivery and reduce yield deviation.

With instant eat soft serve desserts this is quite easily achievable. Stored in a canister, inclusions for soft serve ice creams are dispensed consistently and evenly into the product, ensuring the customer receives a regular quantity of inclusions per serving that does not adversely affect the overall eating experience.

Fudge and harder cookie pieces are the ideal inclusions to work in this environment, as they are added immediately before serving and the texture of the product therefore does not change from its original form. This quick delivery method helps to operate and manage the serving size of inclusions and helps guarantee the customer’s experience with the product is not tainted.

Adding softer inclusions without clumping can be a real challenge, which is where alternative scooping methods come into their own to avoid this issue. It is also important for manufacturers to develop softer products such as cookie dough that can withstand portioning.

Serving & Storage Considerations

The key requirement for many QSRs/casual dining operators is to try and achieve the longest possible shelf life at ambient temperatures, regardless of whether an ingredient is supplied ambient or frozen.

Delivering items which possess more moisture and provide consumers with softer or chewier textures can be a real challenge, especially when operators need their products to possess longer shelf lives. One way in which to overcome this issue is to supply frozen items which remain temperature controlled throughout their distribution chain to stores. These can subsequently be defrosted and given operationally feasible secondary shelf lives at restaurant level. Packing into smaller pack formats can also ensure this approach remains operationally feasible, whilst still delivering indulgent textures.

If we look at brownie pieces, supplying and transporting them frozen ensures that they maintain the moisture and texture that a customer would expect from a brownie. Alternatively, the same brownie piece can be double baked by the manufacturer to reduce moisture content which would then allow the inclusion to be shipped and handled at ambient temperatures.

A new trend is emerging for “instant eat” dessert bars and kiosks, particularly in the Middle East, Asia and warmer European countries. Customers purchase desserts and consume them straight away, as opposed to the traditional approach of buying a hamburger and dessert at the same time and keeping the dessert back to eat at the end of the meal – potentially impairing the texture of any dessert inclusions.

Customer Choice

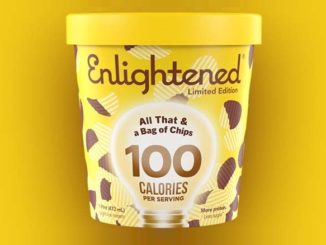

Texture combining of different inclusions is prevalent across many dessert lines in the current marketplace available to consumers. Ben & Jerry’s recently launched an ice cream topped with a chocolate ‘lid’ and Magnum has created an ice cream pint encased in a hard chocolate shell. Haagen-Dazs has also developed a multi-textural ice cream product that combines bites of chocolate with velvety ice cream in one spoonful. It’s clear that texture is a huge trend and selling point – and it isn’t slowing down. QSRs have incorporated texture into their dessert lines for many years – not least with the Crème Egg McFlurry boasting large chocolate pieces as the hero product.

What’s next?

Foodservice outlets are always looking for novelty for an edge over their competitors, and there’s no doubt that engagement with all the senses will dictate market developments in desserts for some time to come. Meanwhile, texture is here to stay and is inspiring key changes in the way that inclusions are used and products are developed within QSRs in particular.